Our Product

Robuschi

Liquid Ring Vacuum Pumps RVS-Series

Advantages at a glance

Robuschi stands out as one of the main supplier of vacuum solutions. Thanks to its liquid ring vacuum pump series, Robuschi is able to offer a wide vacuum range, capable of achieving up to 33 mbar (a) and of sucking gas and vapors without contamination from lubricants and with nearly isothermal gas compression.

Robuschi has introduced a new series of liquid ring pumps and compressors in a monoblock design, tailored to deliver exceptional performance and efficiency. These new models cover a wide range of applications, providing reliable solutions for industries requiring robust and efficient fluid handling.

The liquid ring vacuum pump series assures reduced water consumption, low noise and vibrations, minimum maintenance. The range includes complete groups (KRVS, CRVS, LRVS), especially developed for the vacuum generation in different sectors.

The main characteristics of the range include:

- Capacities up to 4,200 m³/h

- Vacuum up to 33 mbar (a)

- Robustness and reliability

- Simple maintenance

- Low water consumption

- Minimal noise emission and vibrations

- ATEX version available according to process requirements

RVS Vacuum Pumps – How It Works

The RVS series vacuum pump is a single-stage liquid ring pump with an automatic discharge valve. The pump consists of a cylindrical element with an impeller that rotates eccentrically. The impeller moves the service liquid (generally water), which, due to centrifugal force, forms a ring, concentric to the cylindrical element. The gas is sucked in through the intake at the front and is then compressed and discharged through the pump’s outlet port.

Liquid ring vacuum pumps must be supplied with clean operating liquid free of suspended solid parts to function properly. Appropriate replenishment with fresh liquid ensures the continuity of operation and performance.

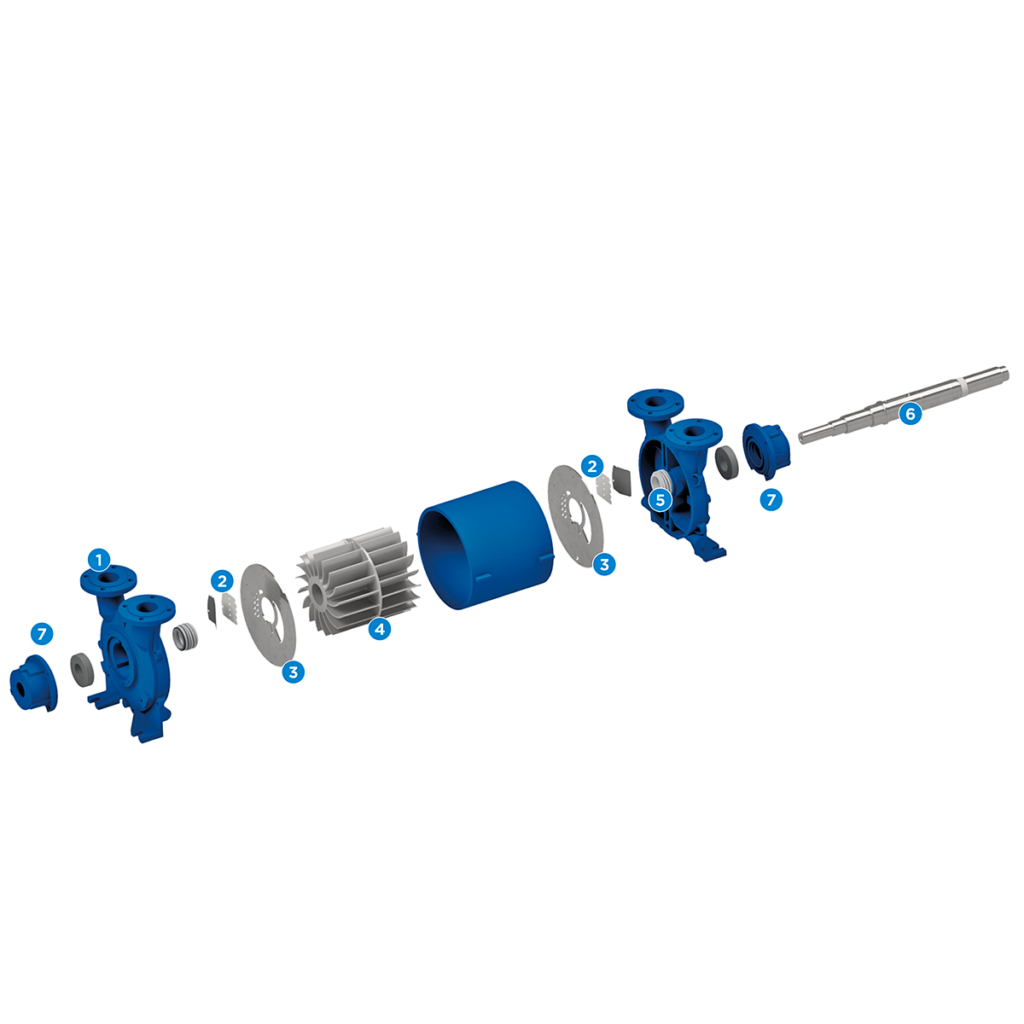

RVS Series Component

- Casing: Reduced consumptions, thanks to the efficient layout of the internal intake and delivery gas baffles.

- Automatic valve: The automatic valve makes it possible to adopt the compression ratio of the pump at the installation conditions, with less

energetic consumption. - Plate: A greater volumetric efficiency is possible thanks to the stainless steel laser-cut patented distribution plate and to the good layout of the intake and discharge lights.

- Impeller: The impeller is fitted with forward curved blades to give the service fluid the energy that is necessary for the compression and the front hub is conical to facilitate the discharge of compressed gasses.

- Shaft seal: The RVS 23-25 includes single mechanical seals flushed from the service fluid. The sizes RVS 30-60 can be installed both packing seals flushed from the service fluid or from the outside, both double mechanical seals.

- Shaft: The heavy-duty shaft is protected from the contact with the service fluid and conveyed gas, except for the RVS sizes 23 and 25, because the are made of stainless material (see the page Material execution).

- Support:

RVS 23 ÷ 25: equipped with two supports with self-lubricating bearings.

RVS 30 ÷ 60: lubrication with external greaser.