Our Product

Elmo Rietschle

Liquid Ring Vacuum Pumps L-Series

Advantages at a glance

Liquid ring vacuum pumps offer numerous benefits including reliable performance, versatility, low-maintenance, energy-efficiency, and environmentally friendliness.

-

-

-

Patented water reclamation system

-

Unique coatings

-

Stainless Steel options

-

Bronze alloy impellers

-

Anti-cavitation as standard

-

-

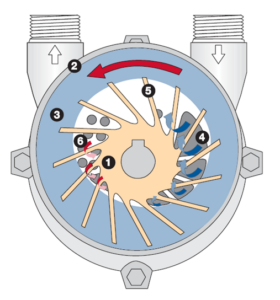

Liquid Ring Vacuum Pumps – How It Works

The impeller (1) is the only moving part. The impeller rotates without contact inside the pump casing (2). A rotating liquid ring (3) seals the impeller on the front and seals its blades against one another. Gas flows through the inlet slot (4) into the blade cells. The impeller is offset within the casing. This creates variable compression chambers between the blades (5), which compresses the gas within a full revolution. In order to stabilize the ring, liquid is also permanently sucked into the compression chamber and is expelled (6) together with the conveyed gas.

L-BL2 Also known as the Elmo Rietschle “Pump in a Box”

These self-contained portable units are oil free and dry air cooled. They include an L-BV liquid ring pump, industrial electric motor, discharge separator, heat exchanger and discharge condenser. To install, simply connect the suction line and motor and fill the water tank— it’s ready to go!

L-BV7 / L-BV2

Our L-BV7 and L-BV2 single stage liquid ring vacuum pumps are efficient machines which save space and consume up to 50 % less water. These pumps are available in various combinations of materials such as stainless steel, bronze, ceramic and cast iron with a ceramic coating. This enables them to be tailored to the respective operating requirements and thus provides long term resistance to corrosion.

L-BV5 Monoblock pumps with the highest volume flow

The L-BV5 family is characterized by a very high suction volume of up to 353 cfm with suction pressures of up to 29 inHg and are primarily used for applications with large quantities of liquids (2BV54). The L-BV5 also simultaneously works as a condenser while suctioning condensable vapors. This enables the suction volume to be doubled.

Reinforced stainless steel shafts, continuously lubricated bearings and a coated pump housing prevent wear and tear caused by solids that are also ingested, and guarantee constant performance and vacuum level, even after many years of use.