Our Product

Gardner Denver

Gardner Denver

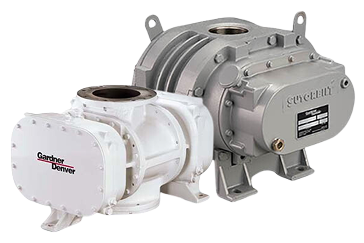

PD Blower Series

Advantages at a glance

Description of Positive Displacement Blower Operation

Positive displacement blowers discharge air out into a pipe or hose in order to move materials. Rotors revolve and air is pulled into the inlet port, air is forced into tight areas between the rotors and casing then is forced to the outlet pipe (or hose). The term “positive displacement” comes from the fact that the volume of air doesn’t change within the blower but is displaced from one end to the other during operation.

Some of the most common industries that utilize positive displacement blowers include:

- Aquaculture

- Chemical

- Dairy

- Cement

- Oil & Gas

- Pulp & Paper

- Power Generation

- Dry Bulk

- Milling

- Plastics

- Wastewater Treatment

- Environmental

-

Type of Blower

-

Gardner Denver’s PD blowers are commonly rotary lobe blowers (e.g., the DuroFlow or CycloBlower series).

-

These use two or three lobed rotors that rotate in opposite directions without contact.

-

-

Working Principle

-

Air enters through the inlet.

-

It is trapped between the lobes and casing as the rotors turn.

-

The trapped air is carried around the inside of the casing (not compressed inside the blower).

-

It is discharged when the lobe reaches the outlet, and pressure builds up from system resistance — external compression (not internal).

-

-

Compression Type

-

These are external compression devices: air is not compressed inside the casing; instead, pressure builds up externally due to system resistance.

-

-

Applications

-

Correct: Used in wastewater treatment, pneumatic conveying, vacuum systems, aeration, combustion air supply, and more.

-

-

Advantages

-

Known for reliability, low maintenance, oil-free air delivery (in many models), and constant flow regardless of pressure.

-

Common Types of Positive Displacement Blowers

The different types of positive displacement blowers may differ in their construction or operation but all are designed to assist with the movement of materials. PD blowers simply trap and then discharge air to propel materials through pipe or hose which makes bulk transport a quicker and more efficient operation.

Straight Bi-Lobe Blowers – employ two figure eight rotors (or lobes) that rotate

Straight Tri-Lobe Blowers – utilizes straight rotors with three lobe design, less noisy and lower pulsation compared to bi-lobe

Twisted Tri-Lobe Blowers – has helical tri-lobe rotors, smoother pulse operation to extend the life of the bearings

Helical Screw Blowers – helical rotors with unique screw design for superior energy savings

Blower Packages – Plug and play simplifies installation and enclosures cuts down on noise levels