Our Product

Robuschi

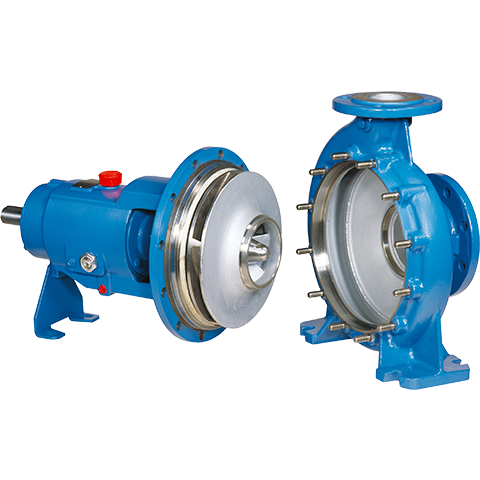

Centrifugal Pump Series

Advantages at a glance

Robuschi centrifugal pumps, PROMIX and PROCHEM, are the perfect solution to convey different types of liquids, offering high fluid dynamics efficiency thanks to their heavy duty features and long life components. PROCHEM is the perfect equipment for chemical processes, infat it is suitable for the conveyance of clear or slightly cloudy, chemically inert or aggressive liquids and solutions with suspended crystals or fibrous materials and outfitted with closed and recessed open impellers. PROMIX series is the ideal pump series for process industry. The series is capable of conveying liquids with high percentages of suspended soild particles, including sludge and it can be equipped with open, closed and recessed channel impellers.

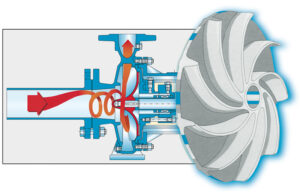

Centrifugal Pumps Working Principle

Centrifugal pumps are hydraulically operated machines characterised by their ability to transmit energy to fluids (in particular to liquids) through the work of a field of centrifugal forces. Their main purpose is to transfer fluids through an increase in pressure. Centrifugal pumps can have different structures, but their operating principle and fluid dynamic characteristics are always the same.

Schematically, centrifugal pumps are formed of an impeller that rotates inside the casing.

The impeller comprises a series of blades, preferably of a radial design, which transmit kinetic energy to the fluid being pumped.

The casing is equipped with suction and discharge nozzles for the fluid being pumped. The suction nozzle has an axis that corresponds with the impeller’s rotational axis, while the discharge nozzle has a normal axis to the impeller axis, but still lying on the plane passing through the axis itself.

Centrifugal Pumps Operating principle

The fluid being pumped enters continuously through the pump’s suction nozzle at the centre of the impeller.

From here it is accelerated in a radial direction as far as the edge of the impeller, where it drains into the casing.

The fluid current is accelerated by the push that the impeller blades, thanks to their curvature, transmit to the current itself. In this way the fluid acquires energy, mainly in the form of an increase in its average speed (kinetic energy).

Inside the casing, the liquid is suitably slowed down thanks to the gradually growing section in the direction of motion.

RN – RNS innovative components assure an high fluid dynamics efficiency

- Rolling-contact oil lubricated bearings, for long service life and high reliability

- Heavy duty pump shaft guarantees high reliability and low deflection for a perfect seal

- Protected shaft from the liquid conveyed (1st – except for RN 32-125, 2nd, 3rd support) in order to prevent corrosion and to allow the use of materials with high-performance mechanical characteristics

- Extremely rugged bearing support constructed following the BACK PULL-OUT system to facilitate maintenance

- The casing is the result of an innovative design with trapezoidal volute to reduce loss and increase the efficiency of the pump

Heavy duty solution: RKNS

The recessed impeller, together with the casing design, allows the RKNS to reach a higher level of efficiency and performance.

The reinforced support with protected shaft is particularly suitable for heavy duty applications, involving, for instance, thick and/or viscous liquids and it guarantees high reliability and long life.

RACN-RACNS series

is equipped with open impeller and designed with wide cross sections between the blades to pump, without any clogging problems, thick or highly viscous liquids with non-fibrous solid particles, and solutions with high solid content. It is suitable for heavy duty in pulp and paper, in sugar, chemical and food processing applications.

The main features are:

- The impeller design makes it possible for the pump to reach a high energy efficiency.

- The casing is provided with replaceable wear plate which can be adjusted externally to maintain the clearance with the impeller constant so as to ensure the high efficiency of the pump.

- Inlet nozzle with large dimensions to ease the suction of liquids containing a high percentage of solid particles and to reduce the impeller wear.

- Heavy duty shaft, flexure on seal less than 0.05 mm.

- Heavy duty support (RACNS) with oversized and higher lifetime bearing and higher stiffness granting pump heavy duty and less vibration.

RCN-RCPN / RCNS-RCPNS series

is designed with wide cross sections between the blades to pump, without any clogging problems, liquids with non-fibrous solid particles. It is suitable for use in the pulp and paper industry, the sugar industry, the chemical industry, in iron metallurgy, in the food processing industry, in sewage treatment plants and shipyards.

The main features are:

- Pump casing designed with open spiral ring to pump liquids containing solid particles and to avoid air bubble formation.

- The casing of RCN – RCNS series pumps is provided with a replaceable wear ring, to pump liquids with abrasive solid.

- Inlet nozzle with large dimensions to ease the suction of liquids containing a high percentage of solid particles and to reduce the impeller wear

- Heavy duty shaft, flexure on seal less than 0.05 mm

RKC – RKCS series pumps

is designed with a special casing in order to generate the pumping vortex. In this way the liquid flows through the pump without entering the impeller vanes. This avoids clogging problems with viscous liquids containing solid particles and fibrous materials, and liquids with air. It is suitable for use in the pulp and paper industry, the sugar industry, the chemical industry, in the food processing industry, in iron metallurgy, in sewage treatment plants and shipyards.

The main features are:

- Replaceable wear plate with special hydrodynamic profile

- Heavy duty shaft, flexure on seal less than 0.05 mm