Our Product

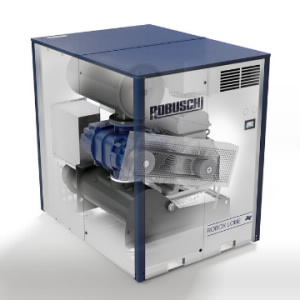

Robuschi

Package Blower Series

Unique Design, Best-in-class Footprint

Thanks to its exclusive features, the new Robox Lobe blower unit has compact dimensions with the possibility of side-by-side installation. It is easy to be installed with no requirements for ducting. The Robox Lobe blower’s compact dimensions will optimise your floor space usage.

One Package Two Technologies (Sizes 3.0, 3.5, 4.0, 5.0)

Take advantage of the one solution for both lobe and screw blower technologies. Whether revamping plants, or your processes, you can review and compare each technology’s benefits for your operation before you commit to buy.

Small Footprint for Minimal Space Requirements (Sizes 1.0, 1.5)

The new additional frames — 1.0 and 1.5 — mark the smallest options within our lobe blower range. The distinctive configuration of the Robox lobe package minimizes its footprint while concurrently preserving and enhancing performance. Depending on the lobe blower dimensions, we’ve managed to reduce the overall footprint by an impressive 20%.

Low Noise

Low noise emissions are ensured by our new discharge and suction silencer design. In addition, canopy enhancements provide noise reduction thanks to special sound proofing material and upgraded panel thickness. In addition, the enclosure air inlet and outlet ducts are muzzled with a lined single-chamber plenum and lined bends.

Easy Installation

Save time and money thanks to the easy and flexible installation of the new Robox Lobe blower. Handle the Robox with ease utilizing the rigid base which has dedicated channels for forklifts. Place it on any even surface, with no need for special foundations. Thanks to its compact design, the Robox can be quickly and easily integrated into your existing system.

Accessible Service and Maintenance

All maintenance operations are easily performed from the front with the removal of the front panel or for bigger frames with the removal of side panels.

For frames 1.0 and 1.5 the all the maintenance tasks, such as oil change, belt replacement, and air filter installation, can be effortlessly carried out by simply opening the rooftop and removing the front panel.

Additionally, air end overhaul and motor repositioning are conveniently achieved through unrestricted top and front access.

RBS – Oil-free Premium Airend

The Robox Lobe blower unit accommodates the RBS airend with three special profile lobes. Combined with a low pulse system, the lobes reduce the residual pressure pulsation of the conveyed gas to less than 2% of the operating pressure.

The RBS airend is equipped with splash-lubricated helical tooth synchronized gears for optimum rotor timing. High quality lobe profile rotors are controlled by three-dimensional instruments for top volumetric efficiency. Durable shaft design compliments the RBS’ reliable operation. The RBS airend is also oil-free certified, Class 0 certification, according to ISO 8573-1.

New Compact Suction Silencer

A newly designed Silencer is equipped with a dedicated filter cartridge for improved reliability and quicker maintenance. This minimises pressure drops. Noise reduction is provided by a new absorptive and reactive internal resonance chamber design.

Robust Discharge Silencer

A Reactive discharge silencer with increased thickness and spark arrester. This design prevents contamination of conveyed gas with sparks generated by the blower. Costly spark traps are no longer necessary.

Check Valve

Proven and robust VRC check valve specifically designed by Robuschi is now positioned within the device to ensure a quick and easy inspection, and replacement.

Lubrication System

A dual splash lubrication system that is simple, reliable and compact. It also provides minimal maintenance without the need for an external oil circuit.

State-Of-The Art Noise Enclosure

The new powder coated enclosure ensures long lasting protection from corrosion, chemicals and the environment. In addition, the noise enclosure’s structure is equipped with tight-fitting frames for the doors and roof support. All the panels/doors are independent of each other and easily removable for inspection.

The new hood design inhibits noise emissions thanks to the enclosure’s air inlet and outlet ducts which are muzzled with a lined single-chamber plenum and lined bends. The closed baseplate is suitable for any type of floor guaranteeing proper noise reduction.

In addition the enclosure provides:

- Side-by-side installation

- Baseplate equipped with dedicated holes for easy access by forklift

- Dedicated access for relief valve inspection and setting to reduce maintenance time

- Access for routine maintenance operations from the front/rear/left/right side of the hood

- Easy service with rear panel opening without the need to disconnect the process pipe

- Electrical cable installation possible both from the top and bottom

| Feature | EL Series | ES Series | GRBS Series | CRBS Series |

|---|---|---|---|---|

| Configuration | Basic skid-mounted package | Skid with integrated silencing base | Weatherproof canopy package | Fully enclosed & soundproof package |

| Flow Rate | Up to 10,500 m³/h | Up to 10,500 m³/h | Up to 10,500 m³/h | Up to 25,000 m³/h |

| Max Pressure | 1,000 mbar(g) | 1,000 mbar(g) | 1,000 mbar(g) | 1,000 mbar(g) |

| Noise Level | ~85–90 dB(A) | ~82–86 dB(A) | ~78–82 dB(A) | As low as 75 dB(A) |

| Drive Type | Belt-driven | Belt-driven | Belt or direct-coupled | Belt or direct-coupled |

| Base Blower | Robuschi RBS | Robuschi RBS | Robuschi RBS | Robuschi RBS |

| Cooling | Air-cooled | Air-cooled | Air-cooled | Air-cooled |

| Silencers | Optional | Integrated suction/discharge | Integrated + canopy | Fully enclosed with sound absorbers |

| Instrumentation | Minimal | Pressure gauges | Gauges + sensors optional | Full control panel + alarms |

| Installation | Indoor | Indoor or outdoor | Outdoor-capable | Indoor or outdoor (quiet zones) |

| Best For | Simple installations | General industry | Outdoor & harsh environments | Hospitals, urban sites, food/pharma |