Our Product

Robuschi

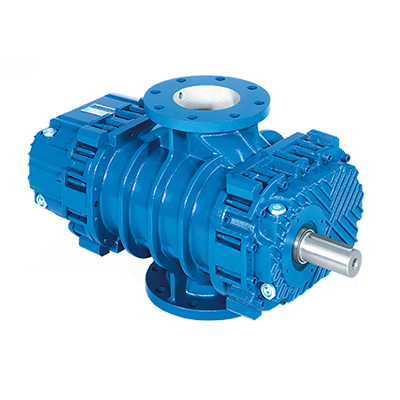

Rotary Lobe Blower RBS-Series

Advantages at a glance

Reliable. Efficient. Built to Perform.

The Robuschi RBS-Series rotary lobe blowers are engineered for demanding industrial applications, delivering high performance with low pulsation and noise. Designed with advanced 3-lobe technology, this series offers robust airflow up to 25,000 m³/h and pressure up to 1,000 mbar(g), all while ensuring easy maintenance and energy efficiency. Whether you’re in wastewater treatment, pneumatic conveying, or vacuum systems, the RBS-Series offers the power and durability to keep your operations running smoothly.

| Technology | 3-lobe rotary positive displacement blower |

| Flow Rate | Up to 25,000 m³/h (14,712 CFM) |

| Pressure Range | Up to 1,000 mbar(g) (14.5 psi) |

| Vacuum Capability | Down to -500 mbar(g) (-7.3 psi) |

| Cooling Type | Air-cooled (no external cooling needed) |

| Lobe Design | 3-lobe profile for reduced pulsation and noise |

| Noise Level | As low as 75 dB(A) with acoustic enclosure |

| Applications | Wastewater treatment, pneumatic transport, aquaculture, vacuum systems, and more |

| Build Quality | Heavy-duty cast iron housing, integrated inlet/outlet silencers |

| Maintenance | Quick service access, long service intervals |

| Drive Options | Belt-driven or direct-coupled configurations |

| Efficiency | High volumetric efficiency, optimized power consumption |

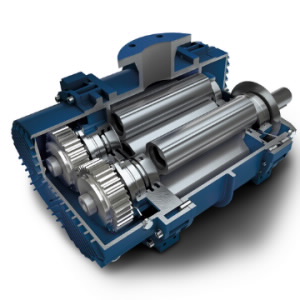

Functionality of the “Roots” Positive Displacement Blowers

The air flow depends on the position and direction of the rotors. The typical installation provides a constant air flow, and that the rotational direction is dependent on the “Roots” blower design. As a side note, the Roots blower design is enduring and durable. The rotary positive air blower was designed in the 1850s and patented in 1860 by brothers Francis and Philander Roots and the Roots name has remained as the description of the design.

The basic principle is as follows: the process starts with air flowing from the inlet port into the element chamber. The timed rotation of the rotors against the wall of the chamber creates so-called “air flow direction”. There is still atmospheric pressure in these chambers.

As soon as the first lobe passes the opening to the pressure side, the system pressure is adjusted. This is called isochoric compression. The rotors seal each other off to the inside, which prevents a change of pressure.

There are variations in the range of tri lobe models. The cooled version is equipped with two cooling coils that maintain the oil temperature below 100°C in all working conditions. It is an ideal blower system for situations when the gas discharge temperature exceeds 140°C.

It comes with two types of coating:

- Niploy (Electroless nickel plating): it guarantees high resistance to corrosion and wear.

- Chemcoat (fluoropolymer lining): it guarantees corrosion resistance for contact with damp substances, nonstick and sliding properties.

The RBS INOX is a stainless steel version of tri lobe blowers, constructed from stainless steel (AISI 316 or DUPLEX), to provide excellent top performance corrosion resistance in a variety of heavy-duty applications such as wastewater treatment, ozone and evaporation processes.

The series of pumps come in a range of models capable of working at top level performance in just about any environment and able to meet just about any service test. When it comes to providing the right tri lobe blower to provide the working pressure that pumps oil free air at the required rates, our range of blowers are hard to beat. Your blower unit can also be customised to provide the exact requirements needed.